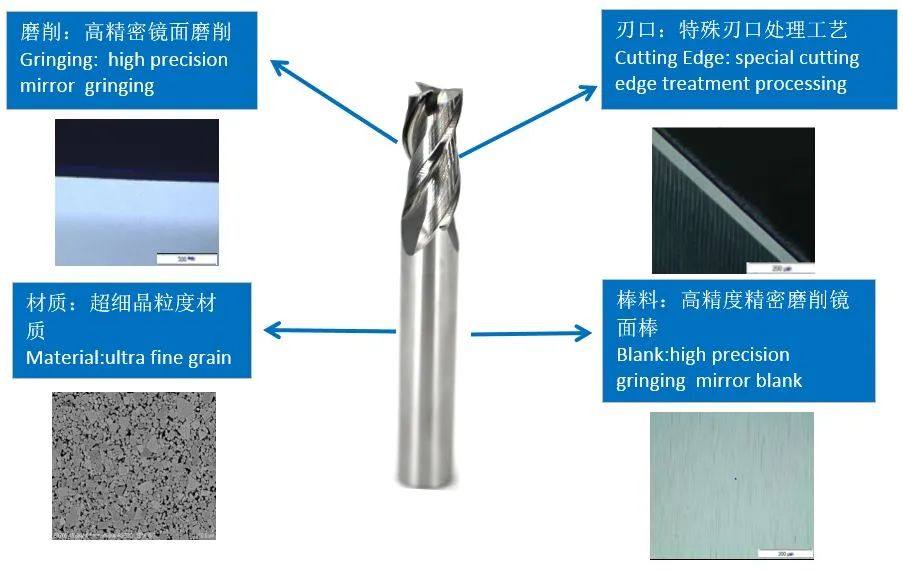

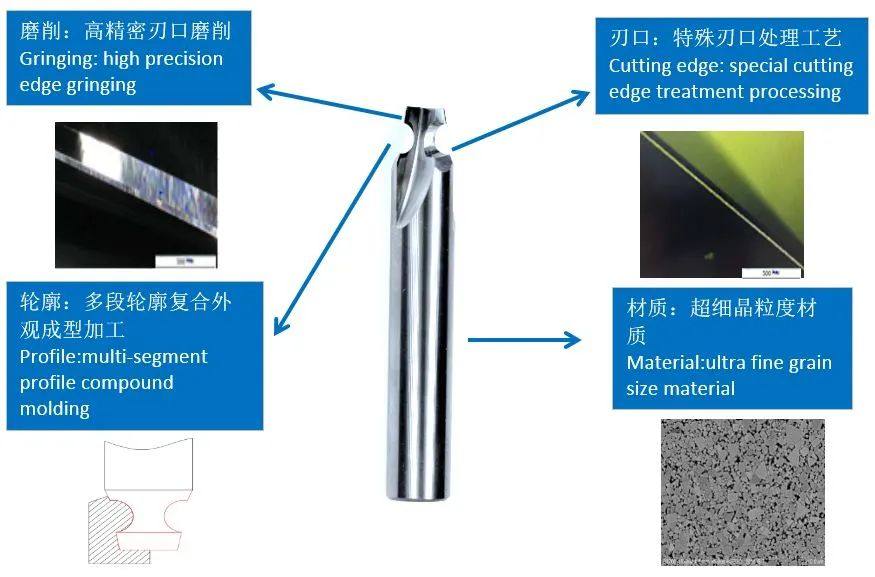

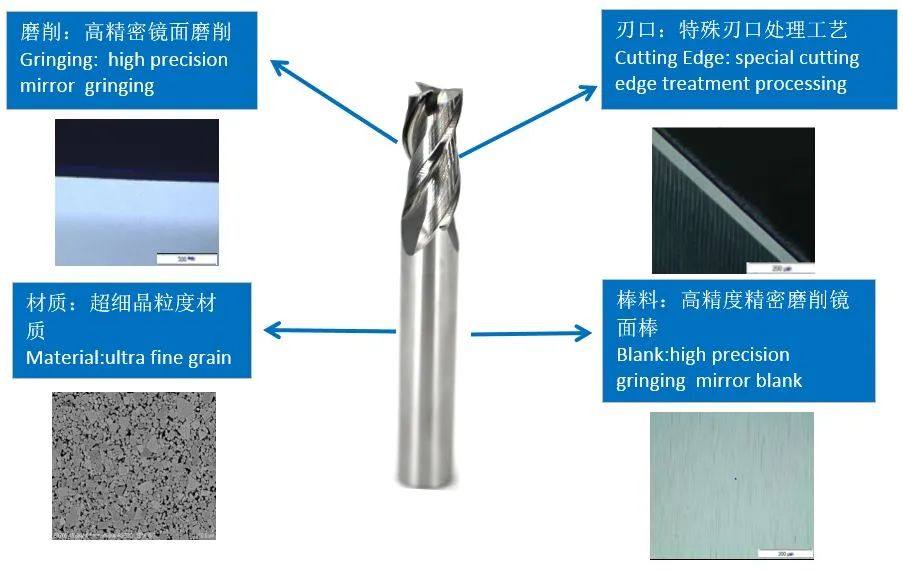

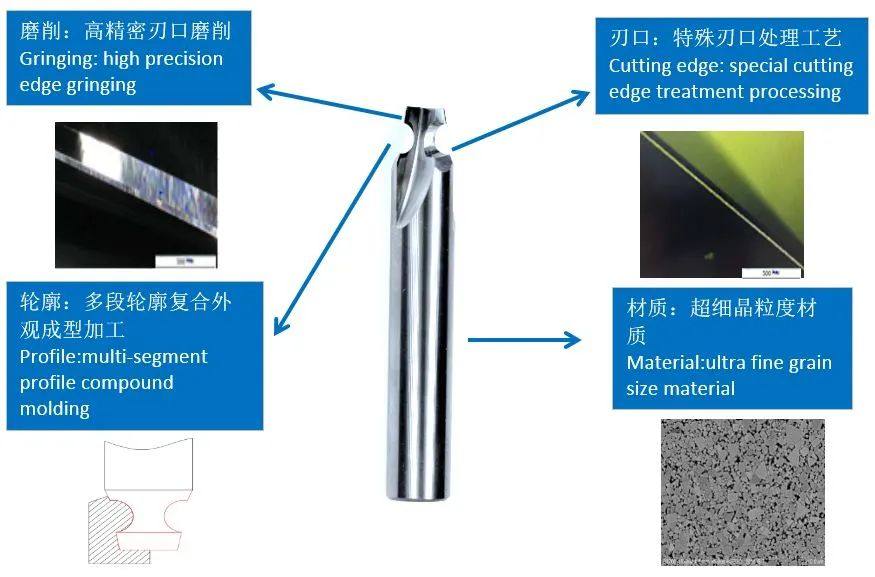

厦门金鹭3C行业铝合金外观加工系列刀具,采用超细颗粒材质,镜面磨削及特殊刃口处理工艺,消除刃口微崩缺,增强抗崩性,达到高寿命、高稳定性要求。

GESAC has launched the 3C industry aluminum alloy series tools of appearance finish milling processing,using ultra-fine particles, mirror grinding and special cutting edge processing technology, It can eliminate the micro chipping of the edge, enhance the anti-collapse property and wear resistance, and also achieve long life and high stability requirements.

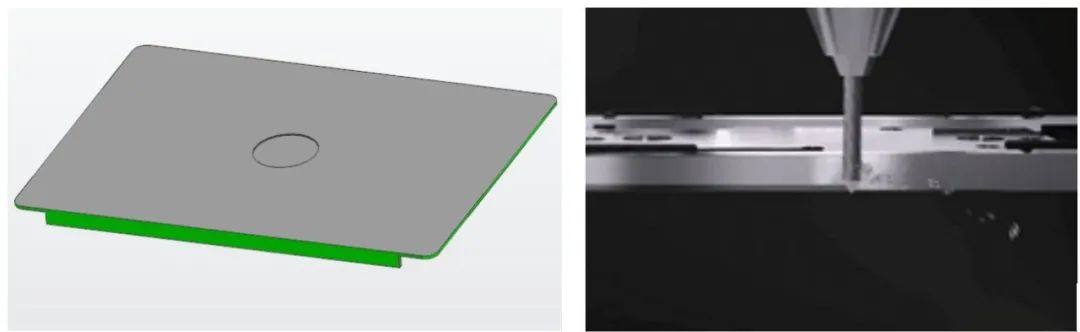

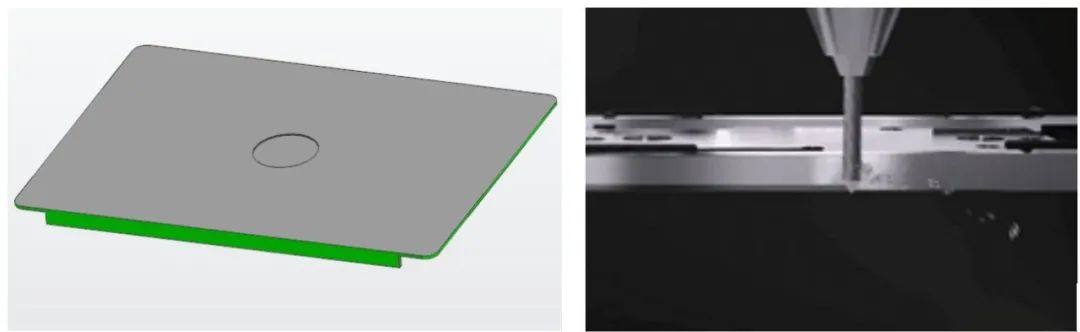

笔记本电脑盖板加工

Processing of Laptop Cover

加工要求 | Require of Procession

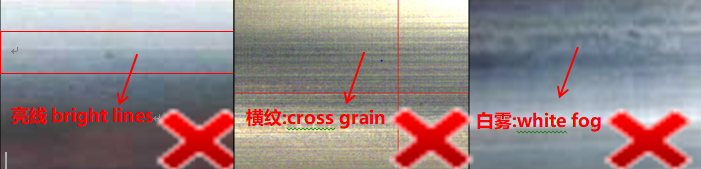

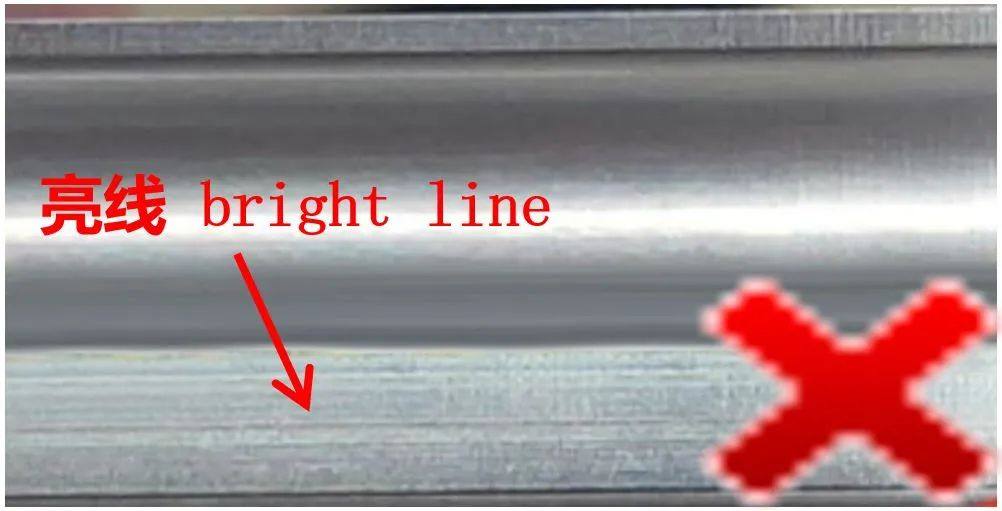

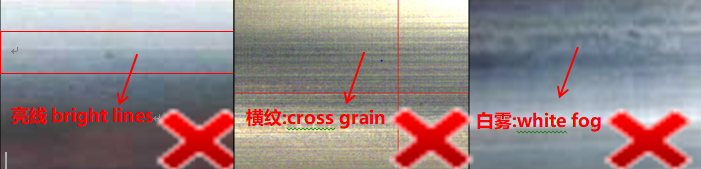

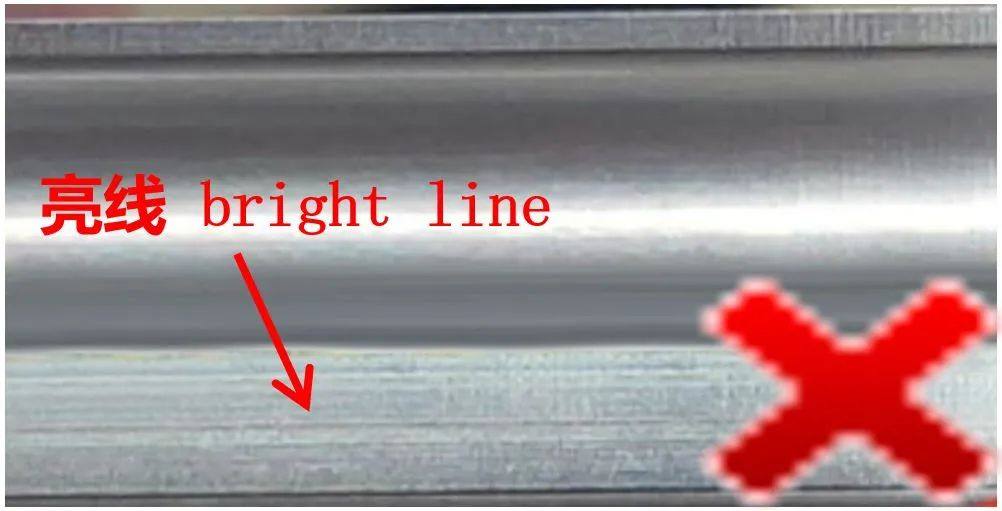

上下盖板作为笔电主要外观件,产品外露表面要求无亮线、无横纹、无白雾等缺陷,这对刀具的磨削、刃口处理提出了极高的品质要求,针对此要求我司开发专用外观加工刀具。

As the appearance part of laptop, the exposed surface of the cover plate requires no bright line,no cross grain,no white fog and other defects.This puts forward higher quality requirements for the grinding and edge treatment of the tools.In view of this requirement,GESAC develops the special appearance processing tools.

产品特点 | Features of Product

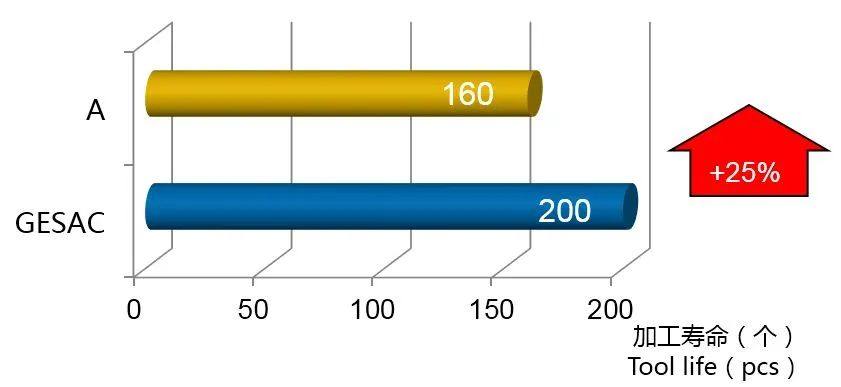

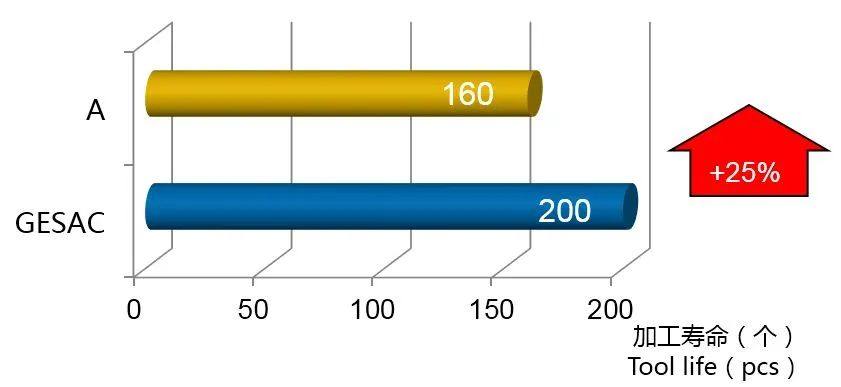

应用案例 | Applications

本案例为笔记本电脑上盖边框外观加工,加工过程中,由于产品边框存在高度渐变、突变的情况,使得刀具在加工中出现磨损不均匀现象,进而导致加工出现横纹。

This case is about the appearance processing of laptop top cover frame. During the processing,the tool wear is uneven due to high gradient and mutation of the product border, which leads to the appearance of transverse grain.

|

刀具规格

Tool Model |

D10*25*75*d10 |

|

加工材料

Processing Materials |

Al6063(HB120-160) |

|

切削速度

Cutting Speed |

314m/min(10000RPM) |

|

进给速度

Feed Speed |

700mm/min |

|

切削量

Cutting Amount |

ap=10mm,ae=0.05 mm |

|

冷却方式

Cooling Mode |

水冷(Water Cooling) |

笔记本电脑转轴加工

Processing of Laptop Shaft

加工要求 | Require of Procession

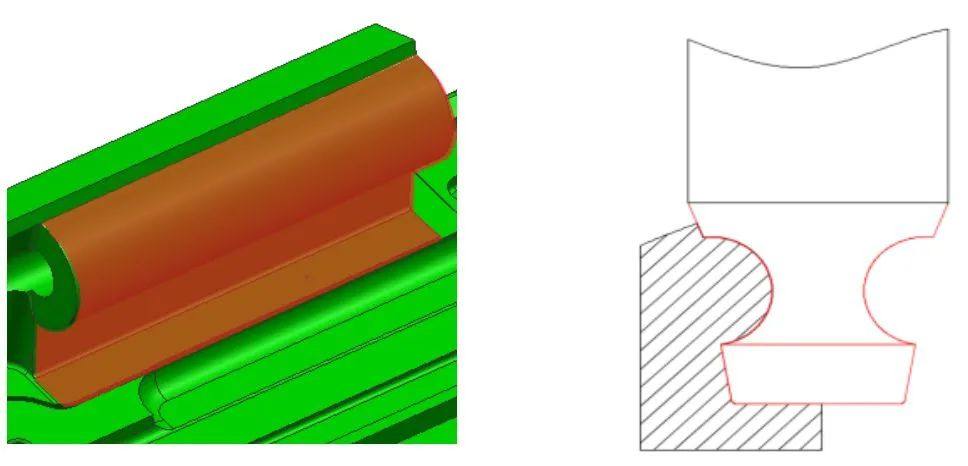

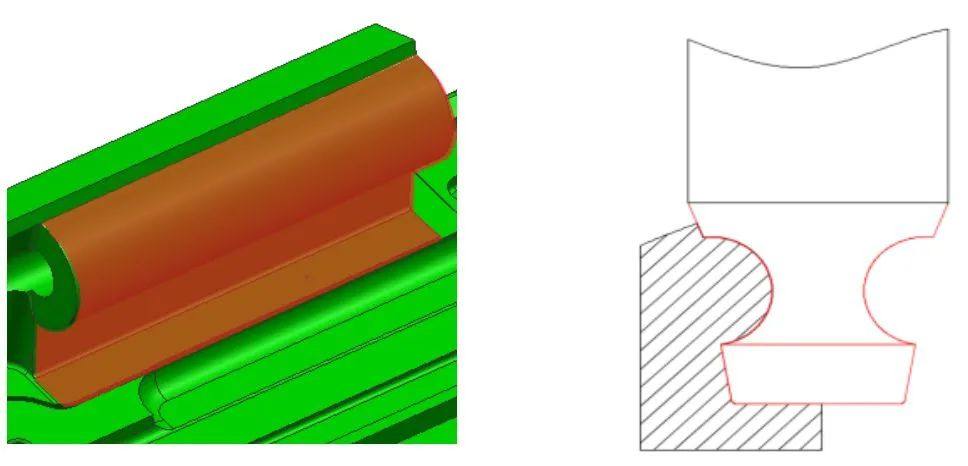

由于转轴结构轮廓由5段轮廓复合成型而成,加工过程中,对刀具的磨削质量要求乘倍提高,产品加工过程中极易造成工件表面亮线等不良情况,要求刀具轮廓线需要进行特殊拟合处理及对刀具刃口进行精密磨削,我司研发出的外观成型刀已能较好的解决此类问题。

As the structural profile of the rotating shaft is formed by compounding of five-segment profile, the requirements for grinding quality of tools are multiplied. It is very easy to cause defects such as bright lines on workpiece surface in the product processing. It is required that the profile line of the tools should be special fitted and the cutting edge of the tools are precisely grinded.The appearance shaped cutter developed by GESAC can better solve such problems.

产品特点 | Features of Product

应用案例 | Applications

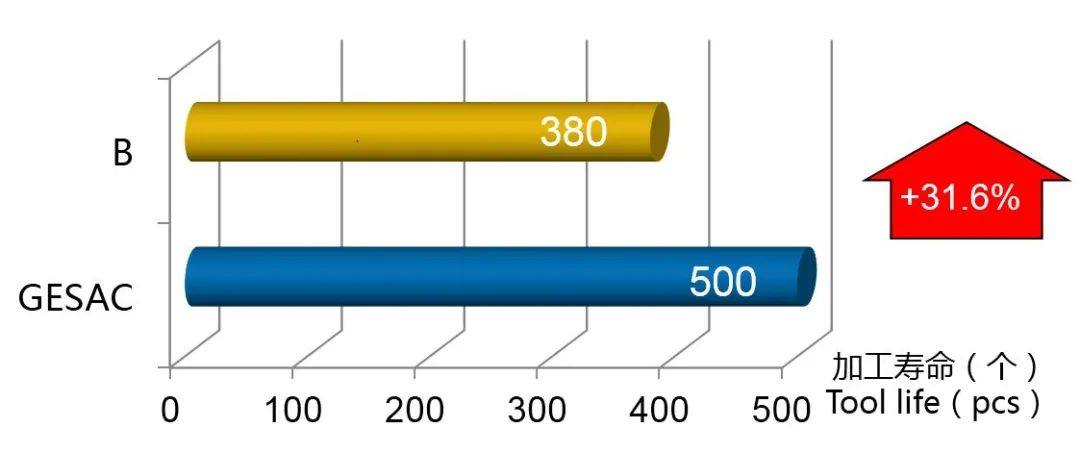

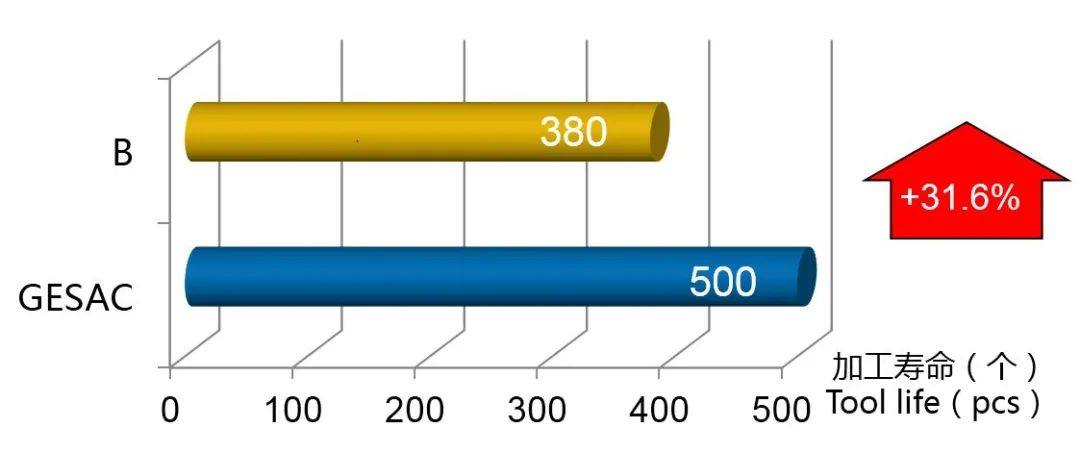

本案例为转轴零件成型外观加工,客户对产品有高轮廓度及外观要求。

This case is the appearance processing of shaft parts, the product has high profile and appearance requirements.

|

刀具规格

Tool Model |

D10*9.5*60*d10 |

|

加工材料

Processing Materials |

Al6063(HB120-160) |

|

切削速度

Cutting Speed |

251.2m/min(8000RPM) |

|

进给速度

Feed Speed |

800mm/min |

|

切削量

Cutting Amount |

ap=9mm,ae=0.1mm |

|

冷却方式

Cooling Mode |

水冷(Water Cooling) |

艾邦建有笔记本材质创新交流群,目前有联想,惠普,DELL,华硕,宏碁,广达,仁宝,纬创,英业达,华勤,巨腾,可成,胜利精密等企业已加入,欢迎更多产业链朋友扫描二维码加入群聊探讨!

原文始发于微信公众号(厦门金鹭切削工具):3C行业笔电外观加工典型刀具应用案例